Driven to be the best.

Our Workshop.

Home » Our Workshop.

We Are New Hampshire

Millworkers & Craftsmen.

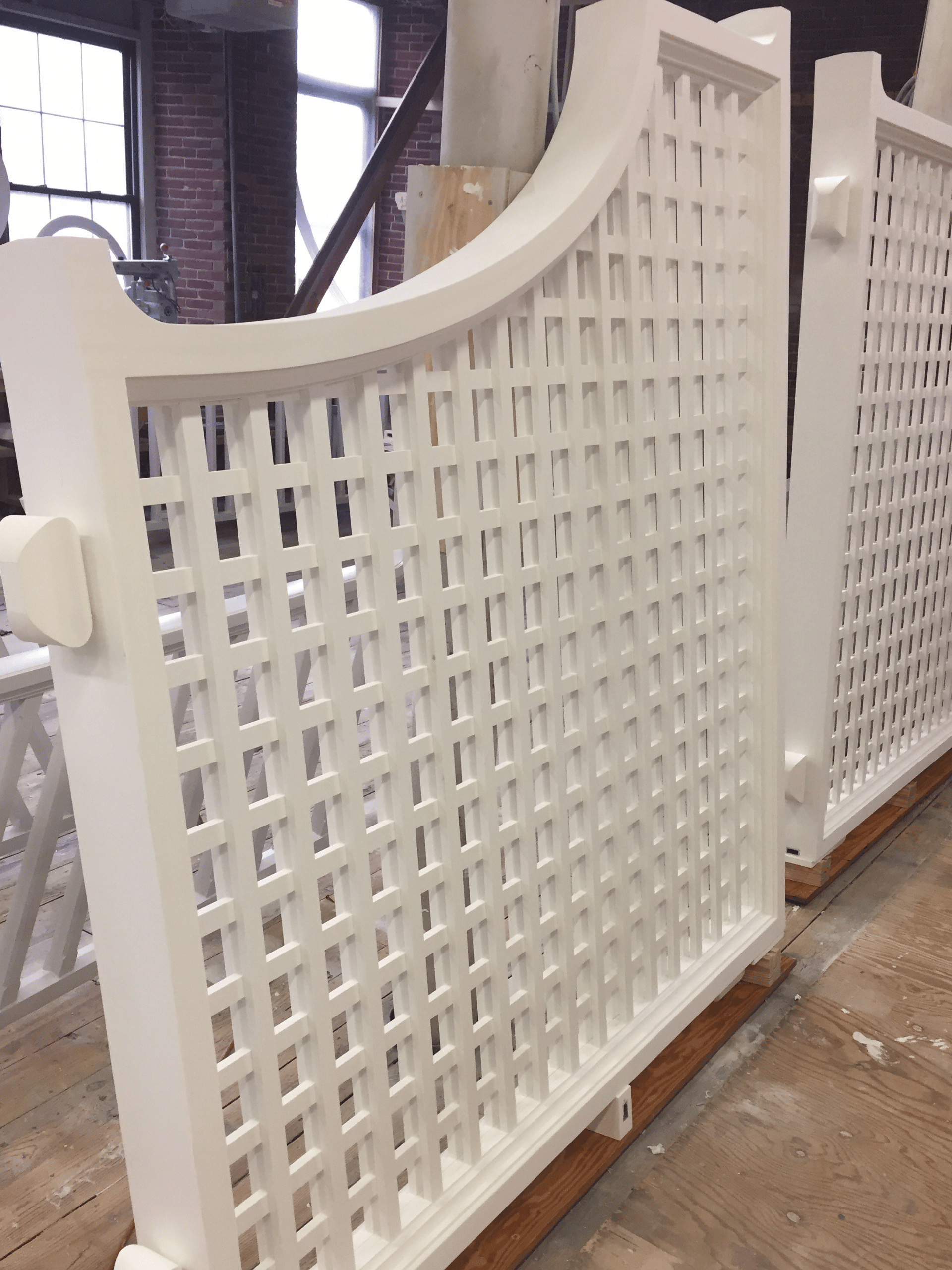

We make custom architectural elements out of cellular PVC.

Although we cover Maine to Florida for most projects, our home base is in the seacoast of New Hampshire. Many of us were carpenters and wood workers in previous careers. We took that expertise to appreciate the flexibility to shape PVC, while still able to deliver a large production build. Armed with CNC routers and other high-end cutting and fabrication equipment we can make virtually anything from a millwork perspective.

Workshop Mock-Ups.

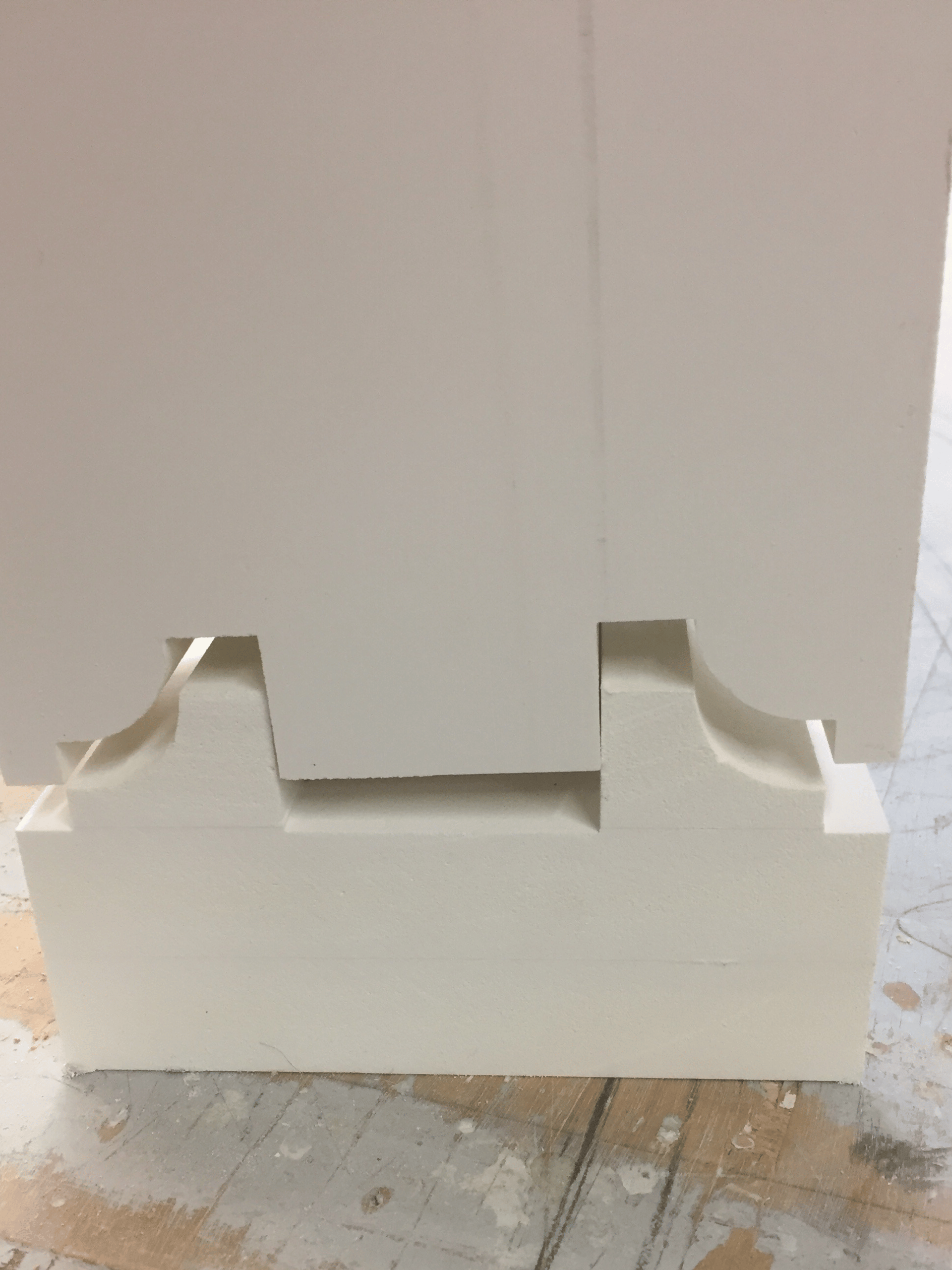

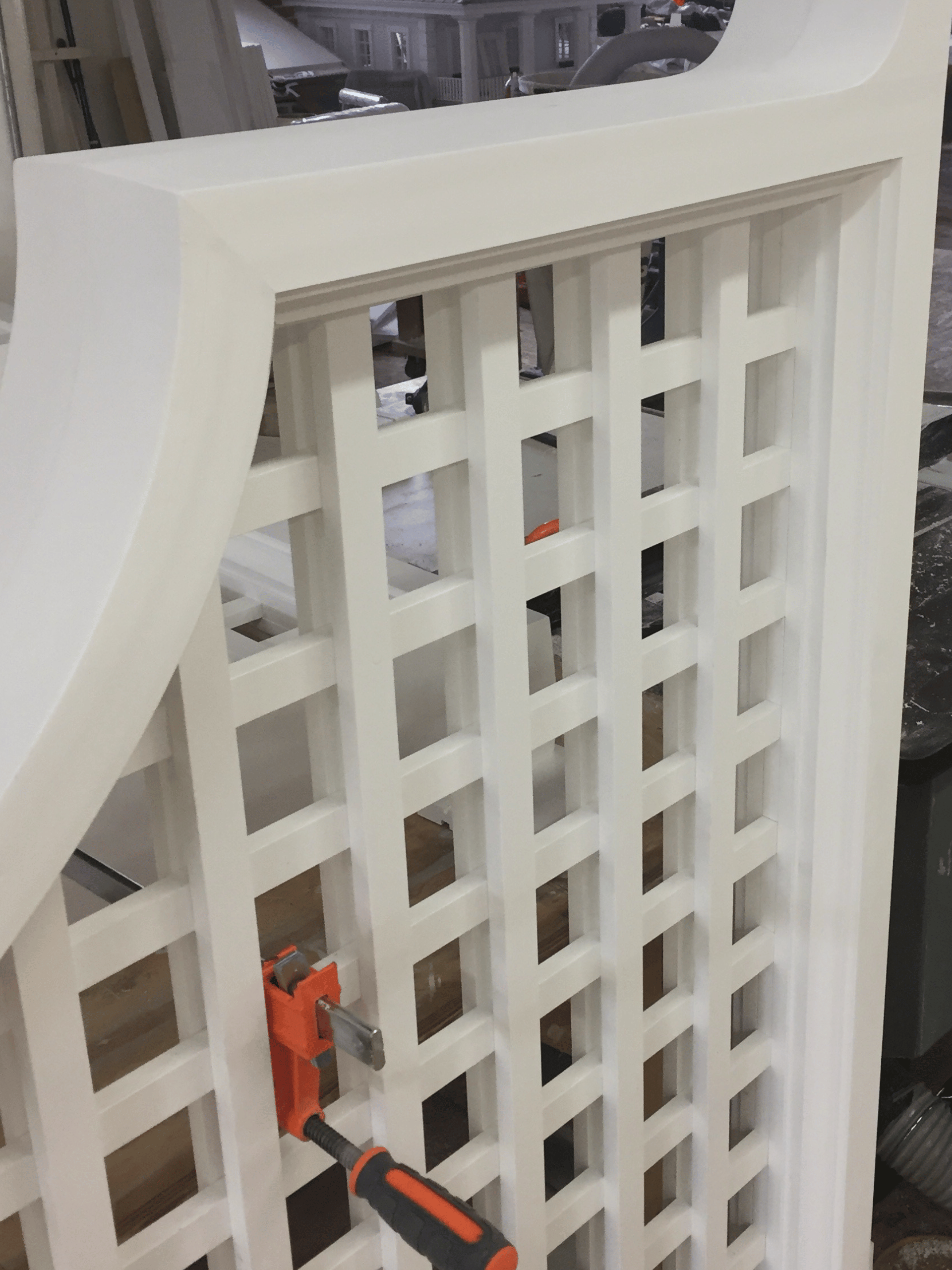

Most of our custom work requires an approval process. We supply a sample of the initial milled product, review how it is made and time saving assembly and delivery. Most manufactures of PVC components will sell you parts that need to be assembled in the field. After 40+ years in construction and installing high-end exterior trim; shop assembled products will always surpass field assembled labor in quality.

How Our Workshop Is

Unique.

#1.

After outlining initial requirements, we review and consult on overall build design.

#2.

Production scheduled after a review of a mock-up version of the final product.

#3.

Assembled in the workshop out of the elements with space to cure the joints and components.

#4.

Final millwork is delivered hand-finished and prepared for contractors to install and paint.

Have a Project to Scope?

Submit a description of your project, requirements and timeline so we can best answer your query.

Corporate Location.

- Address: 10 Willand Rd, Somersworth, NH 03878

- Hours: Mon-Fri 8:00AM - 5:00PM

- Phone: 603-692-4140

- Email: john@shorelinemillwork.com