Home » By Product. » Moulding Projects.

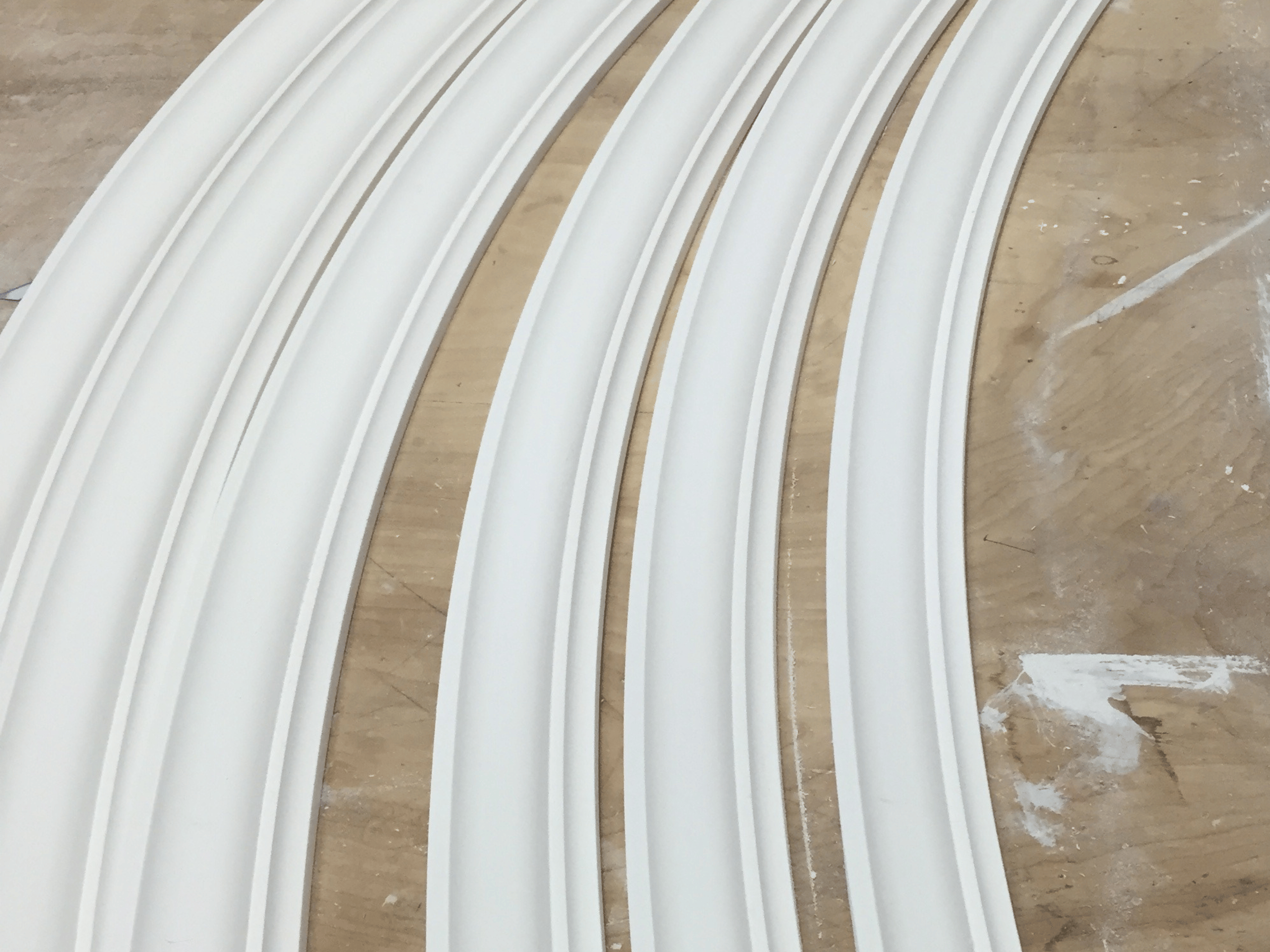

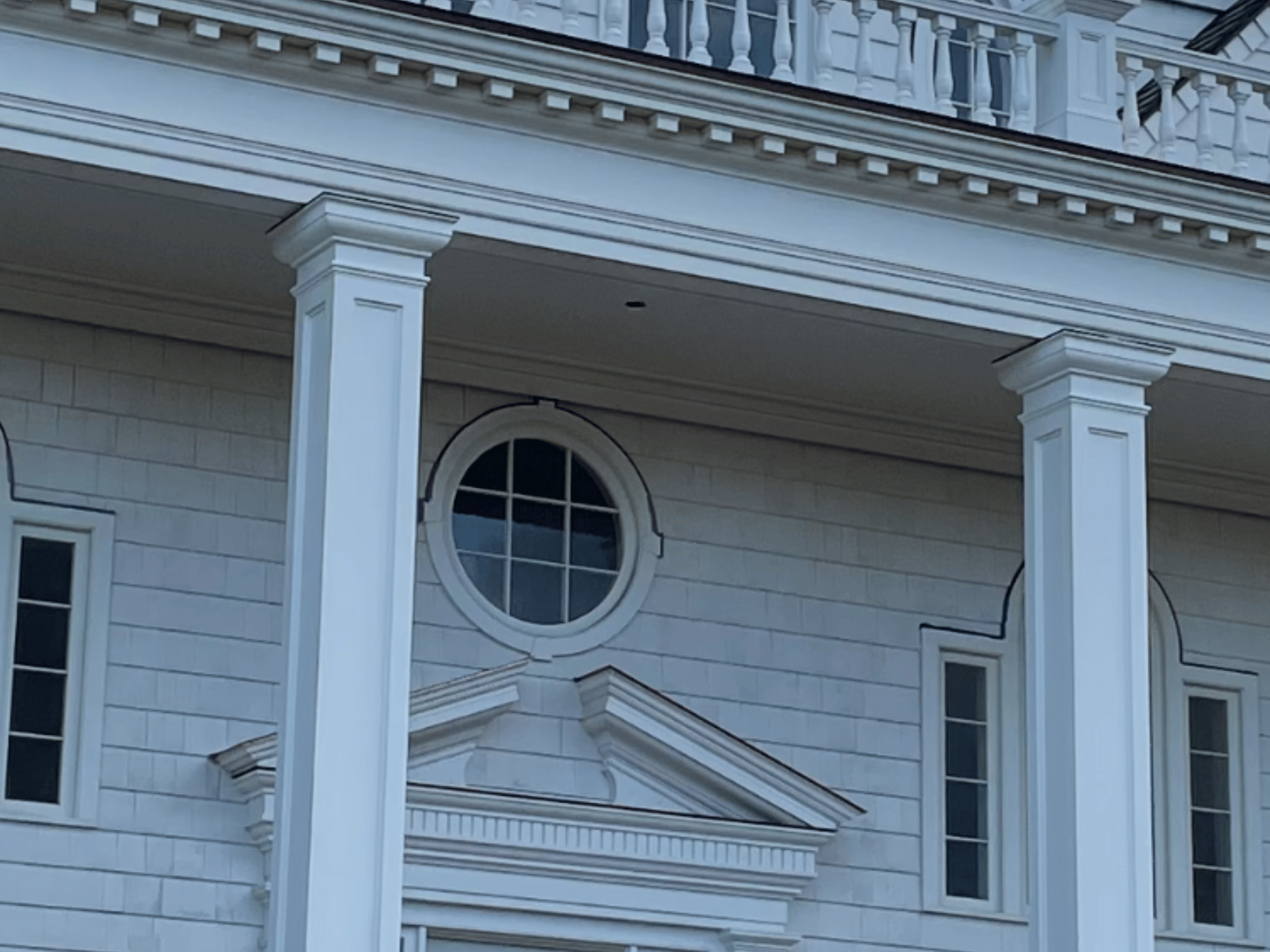

Chosen for custom curved or intricate designed moulding at a large production scale. This allows the architect or builder to order what is needed to complete the build with one vendor with their own specifications. This guarantees fit and better water resistance as well as longevity for the look you want to deliver for the project.

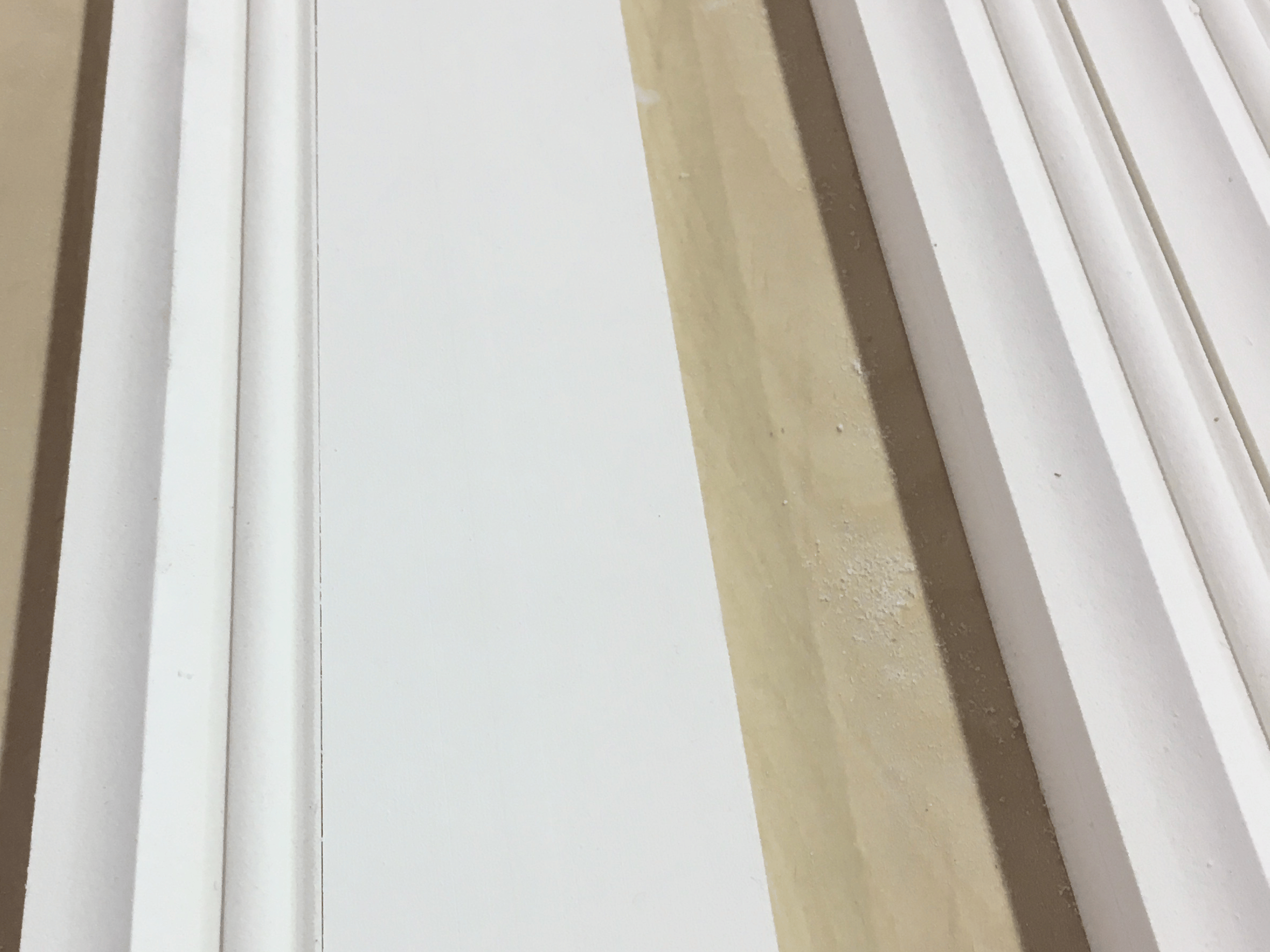

Moulding and trim is a perfect area where cutting corners can be a visible eye sore. The need for perfection and precision at installation can be difficult for large intricate orders. Our pre-assembly process and final product delivery is included in our millwork projects with your unique property as the measure. Each individual project can vary, so final assembly is built to fit.

You get one vendor delivering the materials and final product to support your unique measurements and needs.

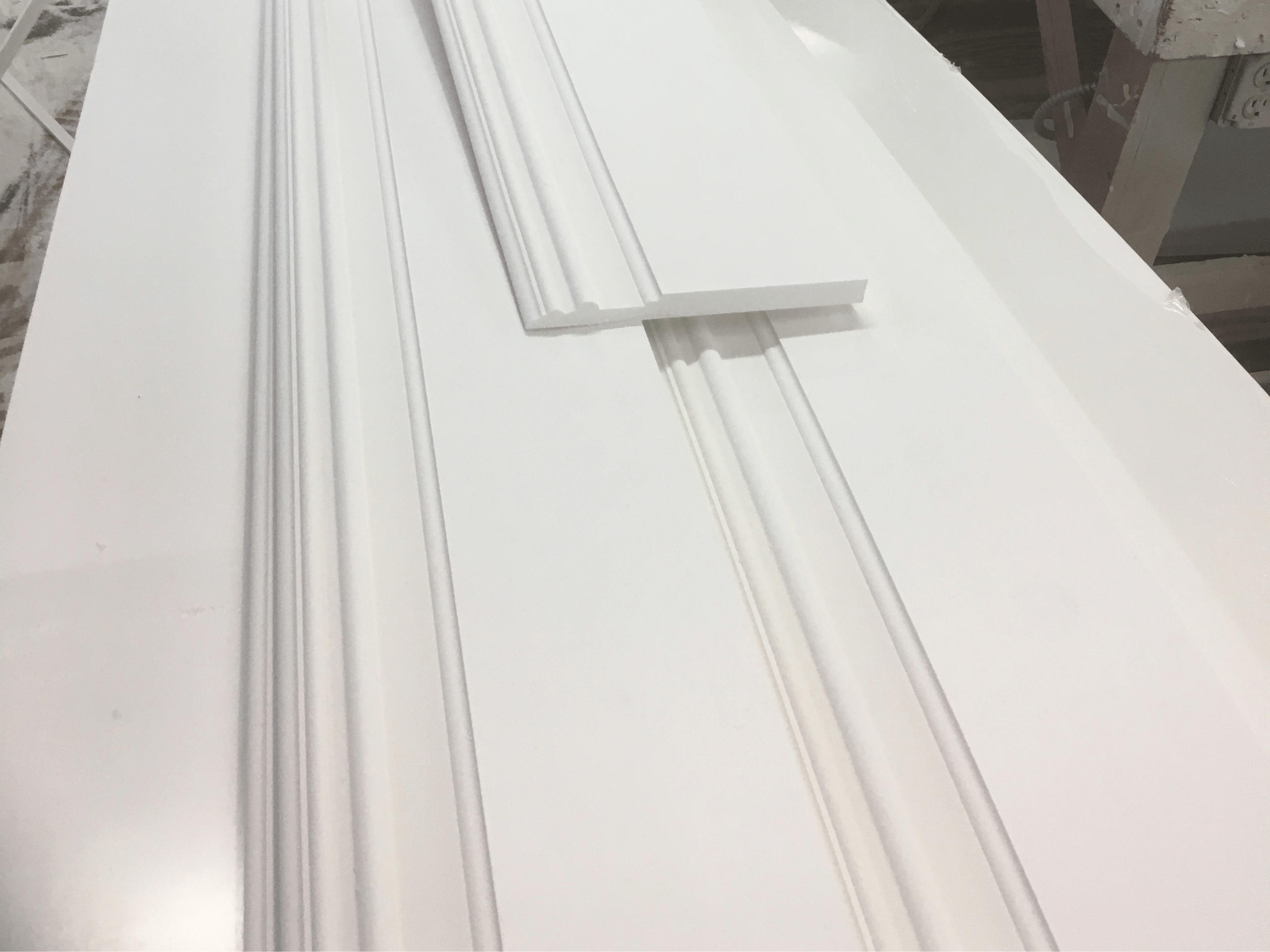

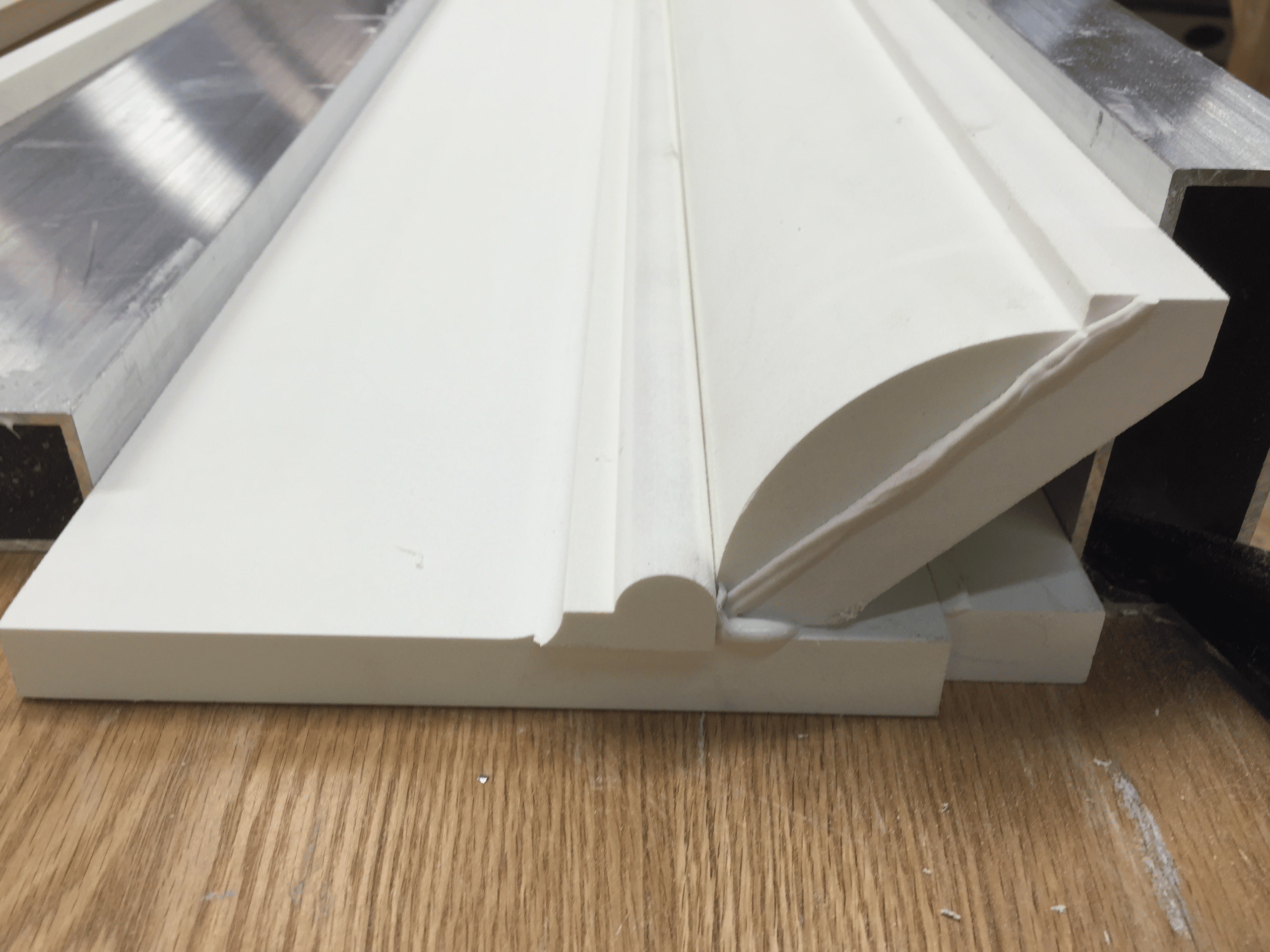

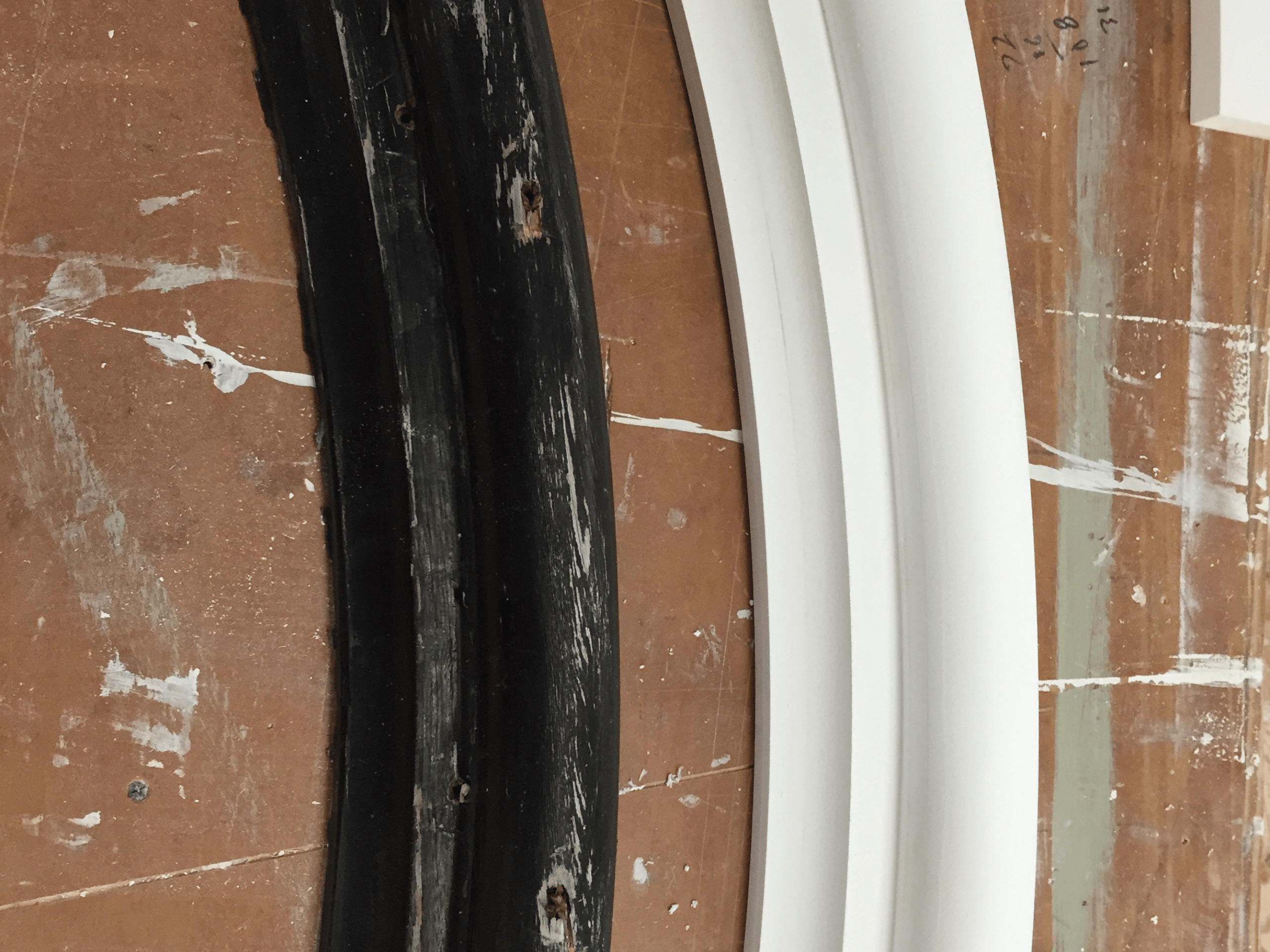

We start the process of assembly by creating the base elements required in our workshop for the full build.

We use high quality materials and we don't scrimp and save when it comes to our final paint-ready products.

We help mitigate the time spent installing a technical or large piece in the field with our pre-assembly.

Prebuilt by craftsmen. Out of the elements, assembled and delivered.

We bring your work of art installation-ready, to help keep your project pacing to deadline. We do as much of the assembly as feasible with a holistic product to reduce time gluing and using multi-vendor materials to stitch together parts purchased from a catalog.

Call for an estimate today:

603-692-4140.